NISSEI’s

Volition

Co-Creation

of New Values

Charting New Frontiers

Through Injection Molding Machines

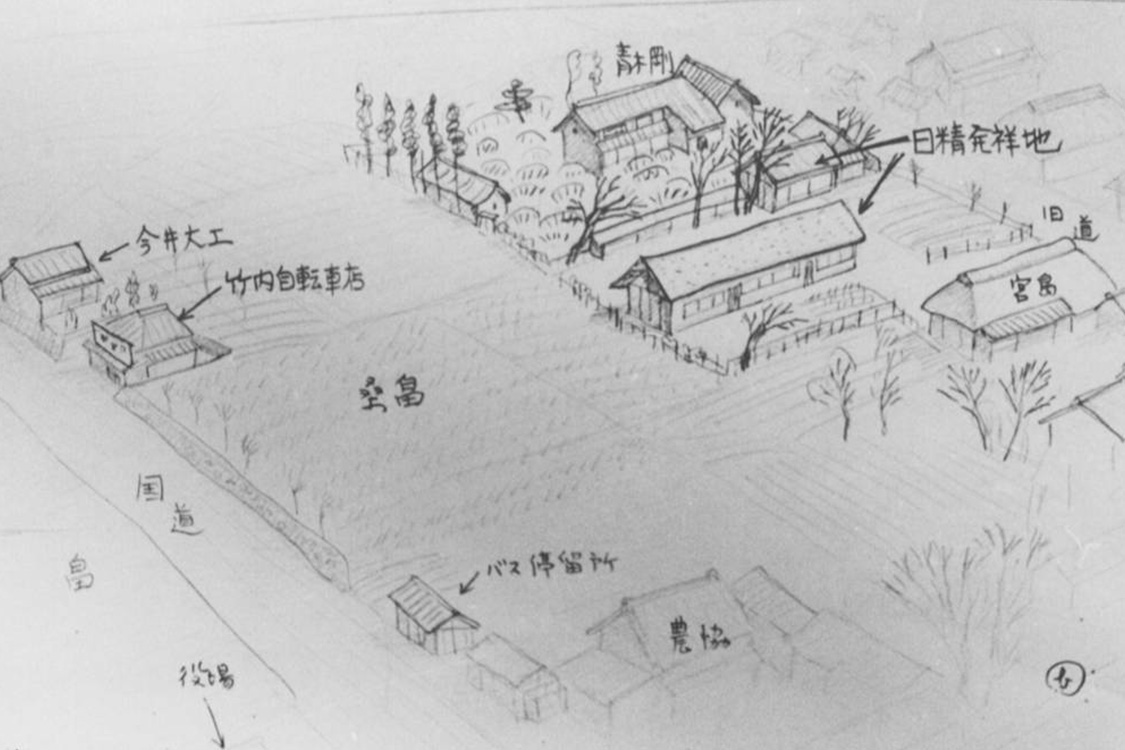

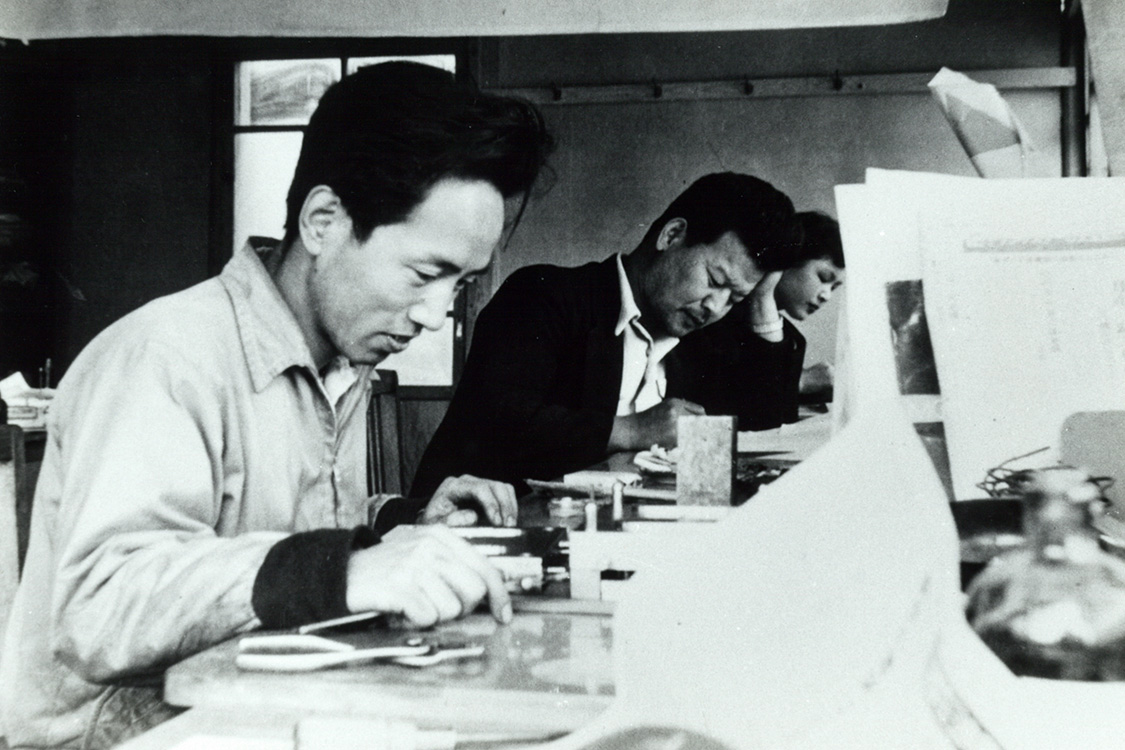

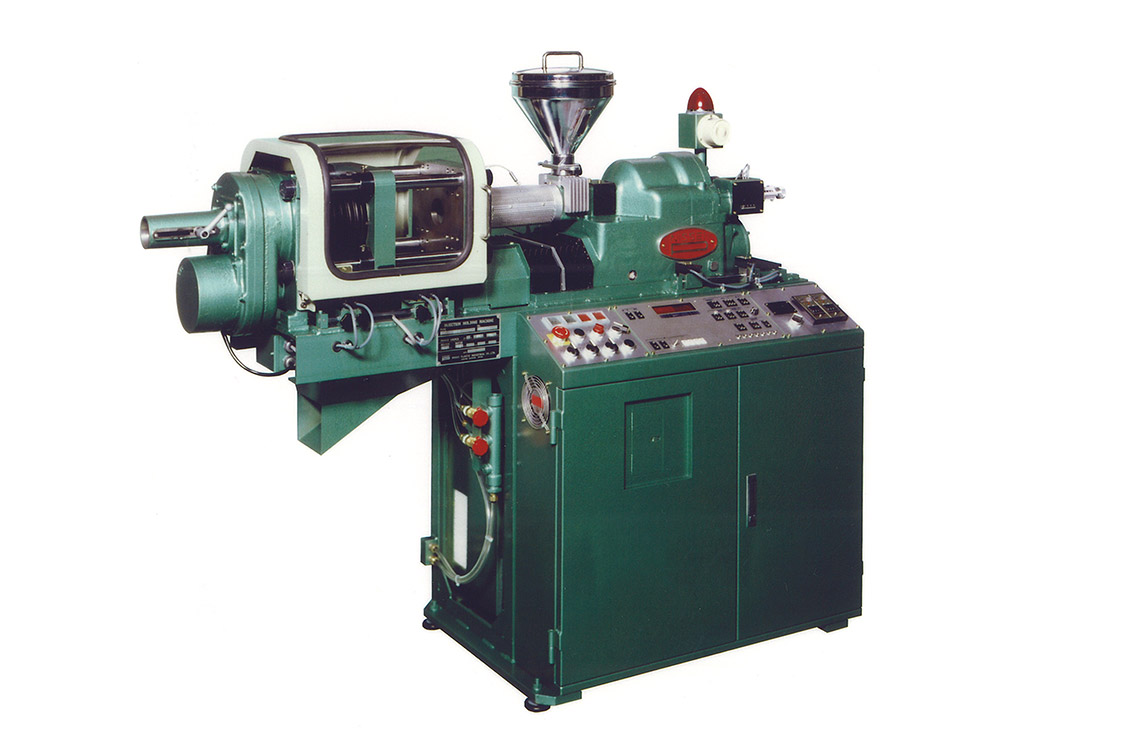

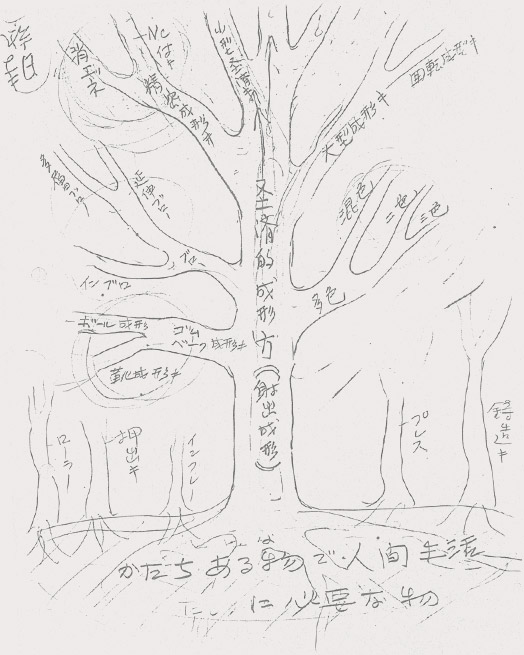

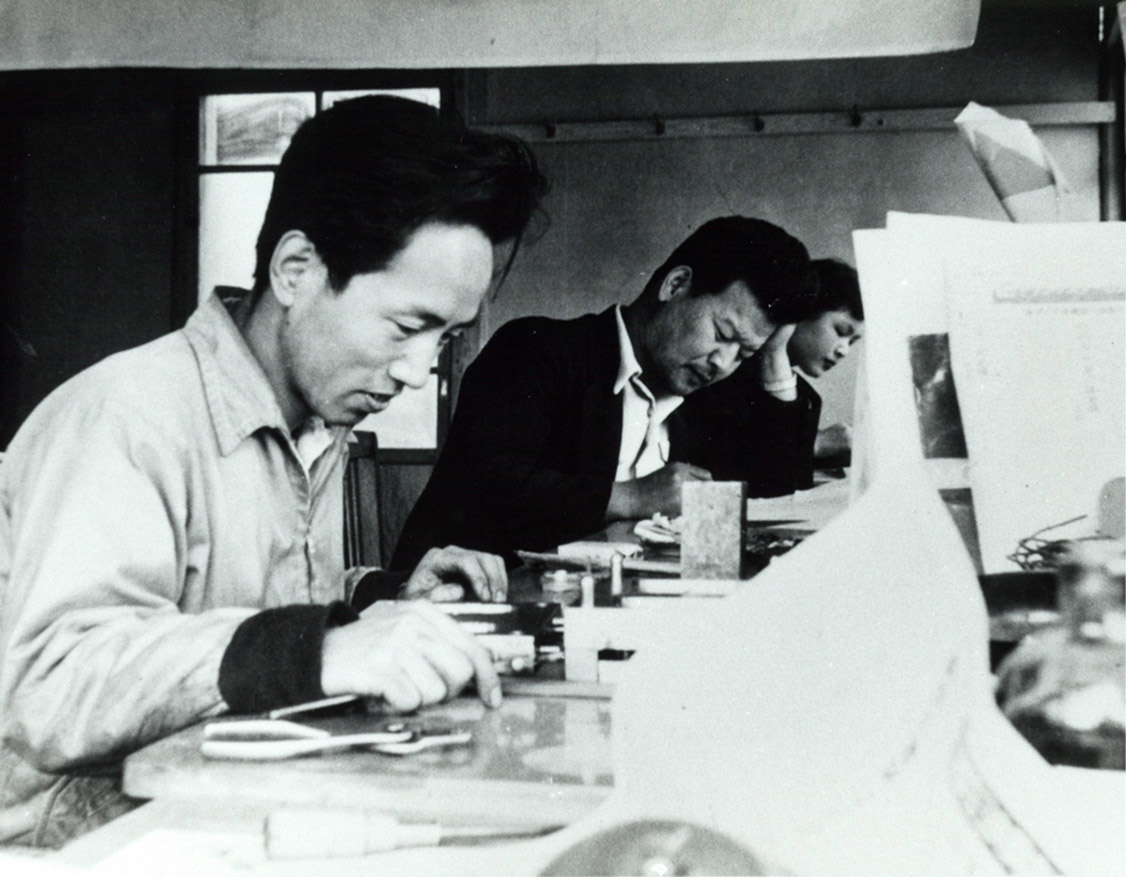

Injection molding machines can mass-produce plastic products efficiently. NISSEI’s founder Katashi Aoki was fascinated by the potentials of plastics right after the World War II when supply shortage and poverty prevailed in Japan. Aoki founded a mold processing business to make everyday plastic items during the period, and it later became an injection molding machine maker, bringing many groundbreaking innovations to the industry.

Today, products made by injection molding machines are used to provide food, medical care, and a variety of other goods to consumers around the world, contributing to ensure safe, secure, and comfortable lifestyles.

But on the flip side, we face new challenges, such as environmental issues and increasing wealth gap between rich and poor.

What is true abundance?

For the benefits of local to global communities and environments, NISSEI wants to contribute in establishing a society in which everyone can share the fruits of growth and development.

As a manufacturer specializing in injection molding machines, NISSEI has raised the bar for its technologies by tackling every aspect surrounding the businesses, including natural environment, factory floor, and work environment. NISSEI continues to explore the potential of injection molding through co-creation of new values with its customers.

Charting New Frontiers

Through Injection Molding Machines

Aspiration

Never Stop Exploring

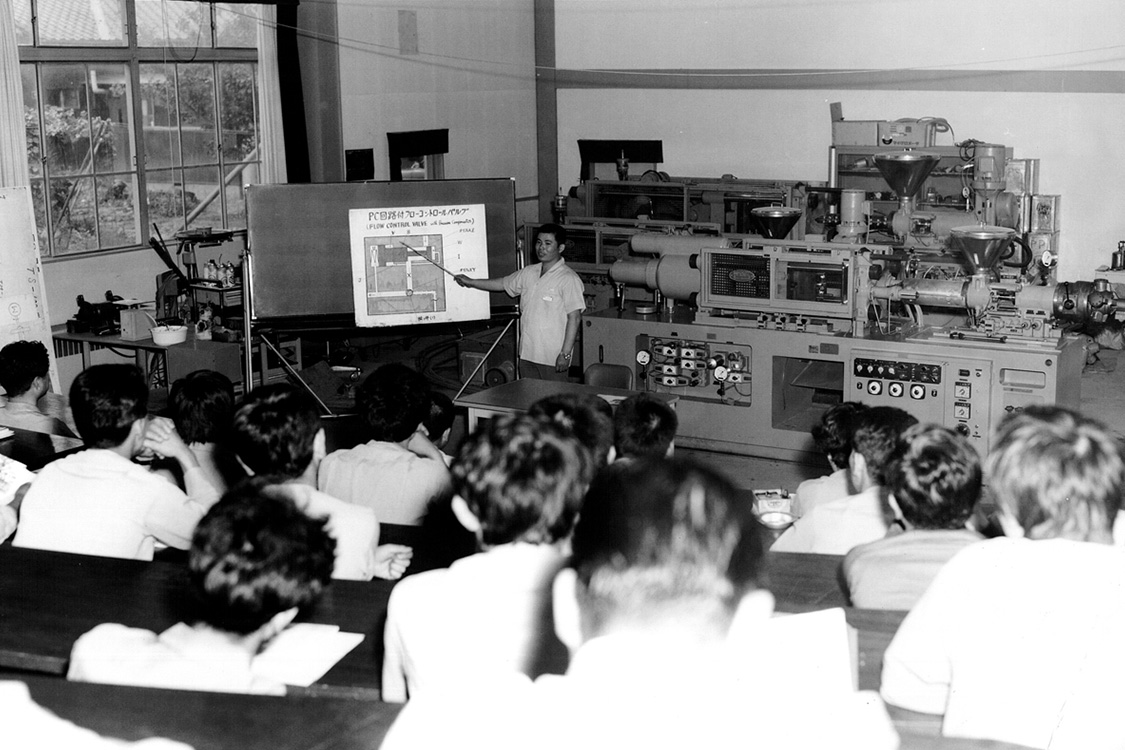

In the specialized filed of injection molding, NISSEI’s founder Katashi Aoki applied his experience in understanding the needs of factory floors, which are the heart of molding businesses, into designing injection molding machines. NISSEI has been carrying the torch of Aoki’s aspiration to dig deeper and push the envelope in utilizing its technologies for a wide variety of applications.

NISSEI continues to innovate injection molding technologies for the global market with its founding spirit.

Volition

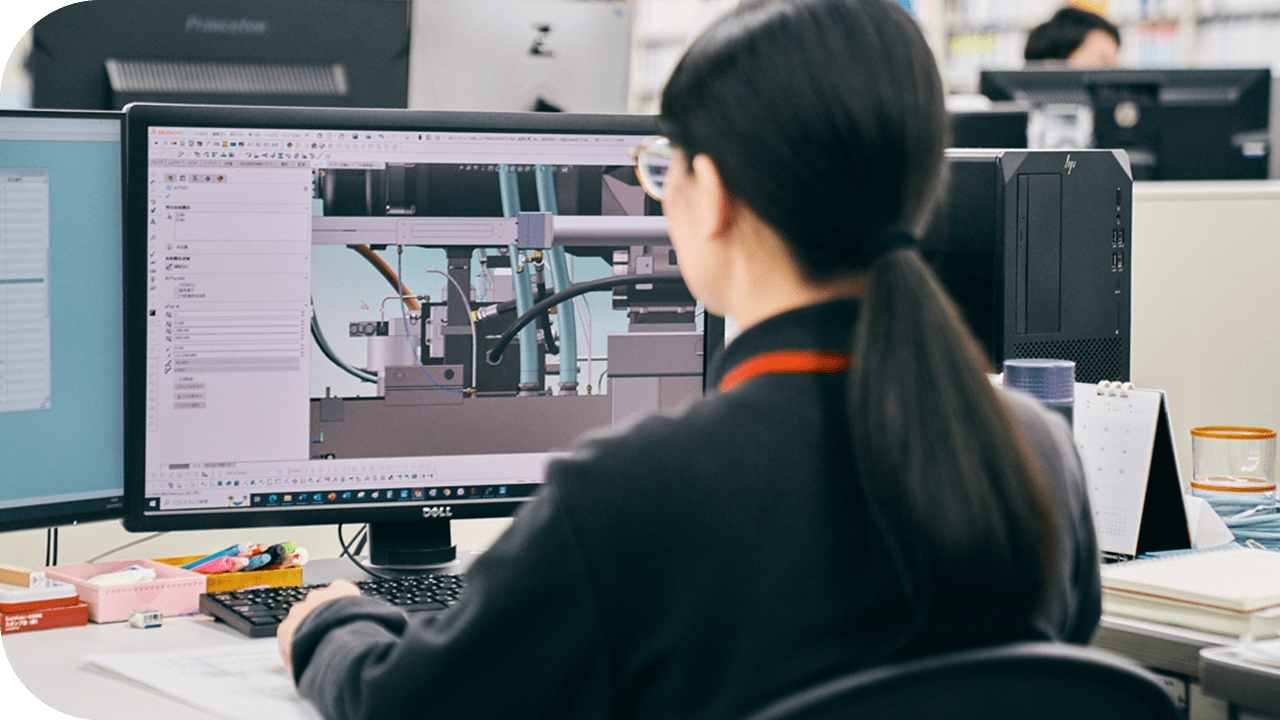

Going Specific, Deeper, and Unlimited Manifest NISSEI’s Volition Into a Form

Manufacturing industries in Japan have been facing many challenges as they entered the 21st century. The key to revival is Japanese technological ingenuity developed over the years, which are made of “Engineering Design” each company possesses. NISSEI Plastic has been helping each client to reinforce their engineering design, offering a variety of solutions to achieve their goals. NISSEI code-named this activity “NISSEI RED,” and “RED” is an acronym for “Reinforcing an Engineering Design.”

Anticipating Customer Needs to Provide Solutions

Industry 4.0 Support

NISSEI stays ahead of competition by offering OPC-UA capability in their new machines and working towards implementing common standards. NISSEI has been collaborating with auxiliary equipment makers actively to achieve seamless linage with other devices as well as adding equipment to the machines that are compliant with global standards for ERP/MES connectivity.

Product Designs for Globalizing Market

The waves of great transformations are sweeping today’s manufacturing sites due to advancing globalization and digitalization. “Industry 4.0” and “Digital Twins” are now being tested to reveal its true potentials. As a dedicated injection molding machine maker, NISSEI has been researching and developing technologies based on “how can they provide solutions to the challenges customers are facing.”

Strong Foundation That Supports NISSEI RED

Grow Further Through “Commercialization of Eco-Friendly Technologies”

NISSEI strives to keep raising the bar on innovation to share a variety of benefits with its stakeholders.

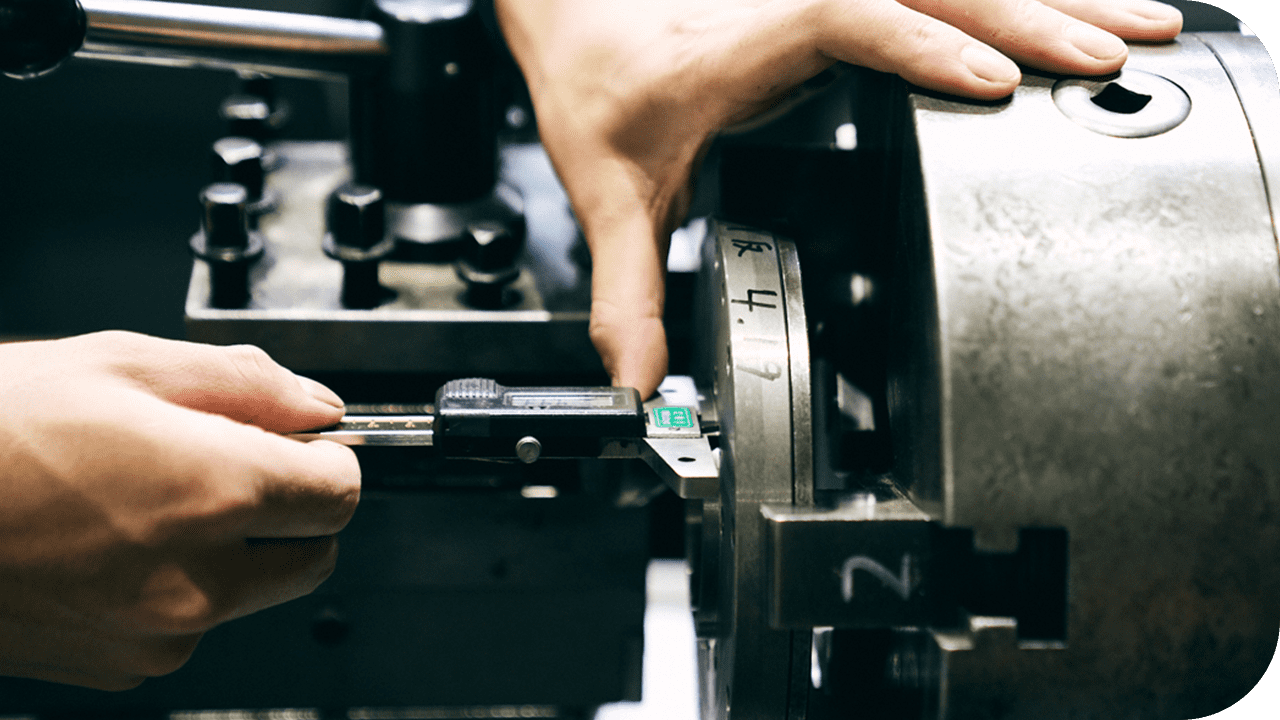

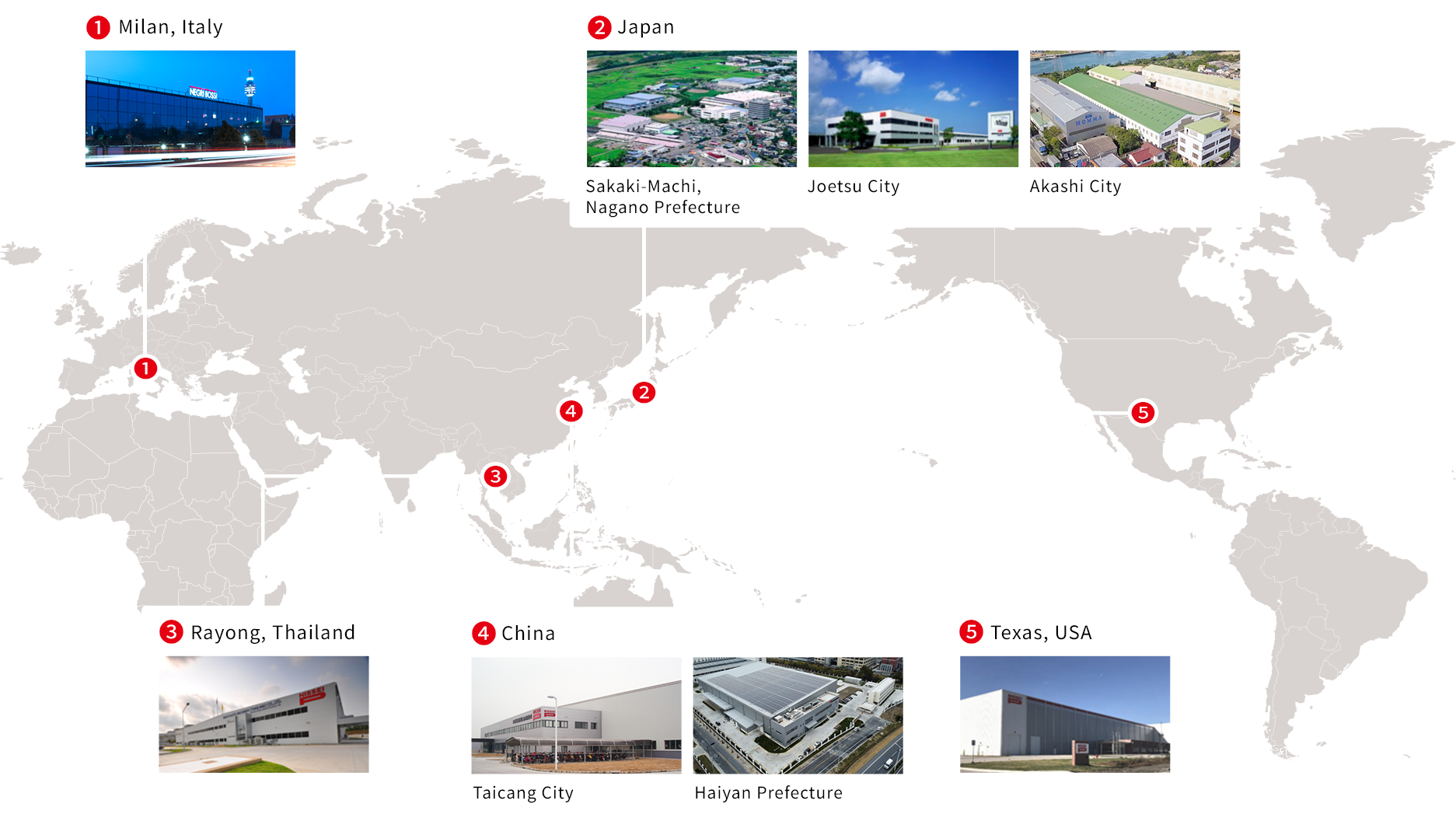

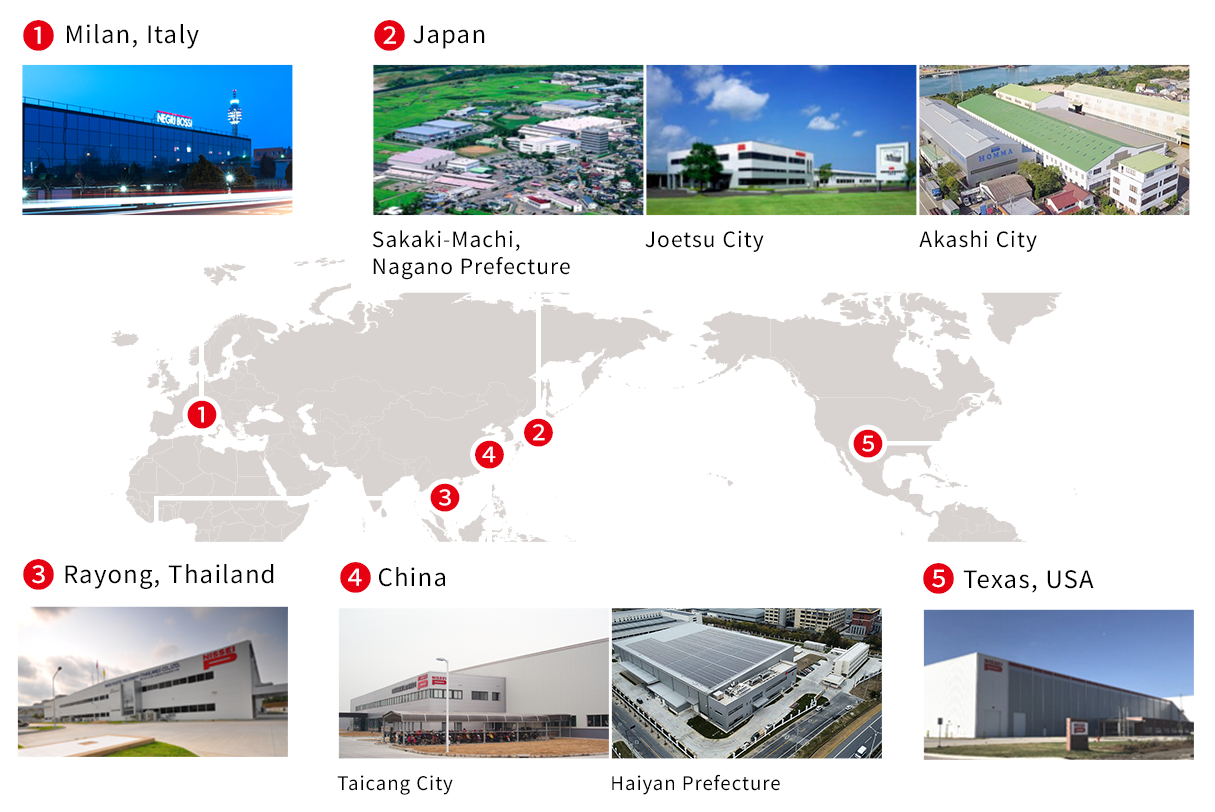

PRODUCTION STRUCTURE

5-Base Production Structure for the Global Supply Chain

NISSEI currently operates five production bases around the globe, including the head factory in Japan. Production capacity, production technologies, quality assurance system, global procurement options have been improved thanks to the 5-base production structure.

In-house production of parts and components also contributes in achieving the SDGs (Sustainable Development Goals), such as reducing CO2 emissions.

TECHNOLOGY

Unique Technologies

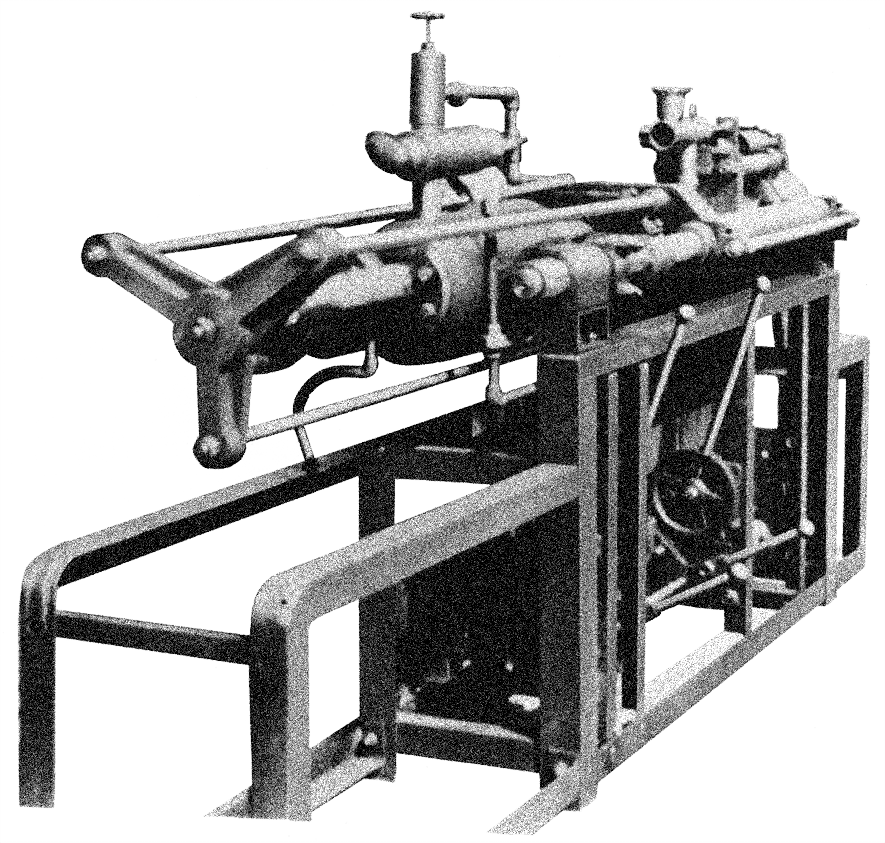

NISSEI was originally established as a mold processing company in 1947. They began modifying and developing injection molding machines in order to achieve excellence in quality and productivity they were looking for. In 1957, NISSEI started the sales of injection molding machine and was reestablished as an injection molding machine manufacturer. Today, NISSEI is only the company in Japan specializing exclusively in making injection molding machines. NISSEI always reflects on the ways molding should be to continuously pioneer new technologies.

SALES & NETWORK

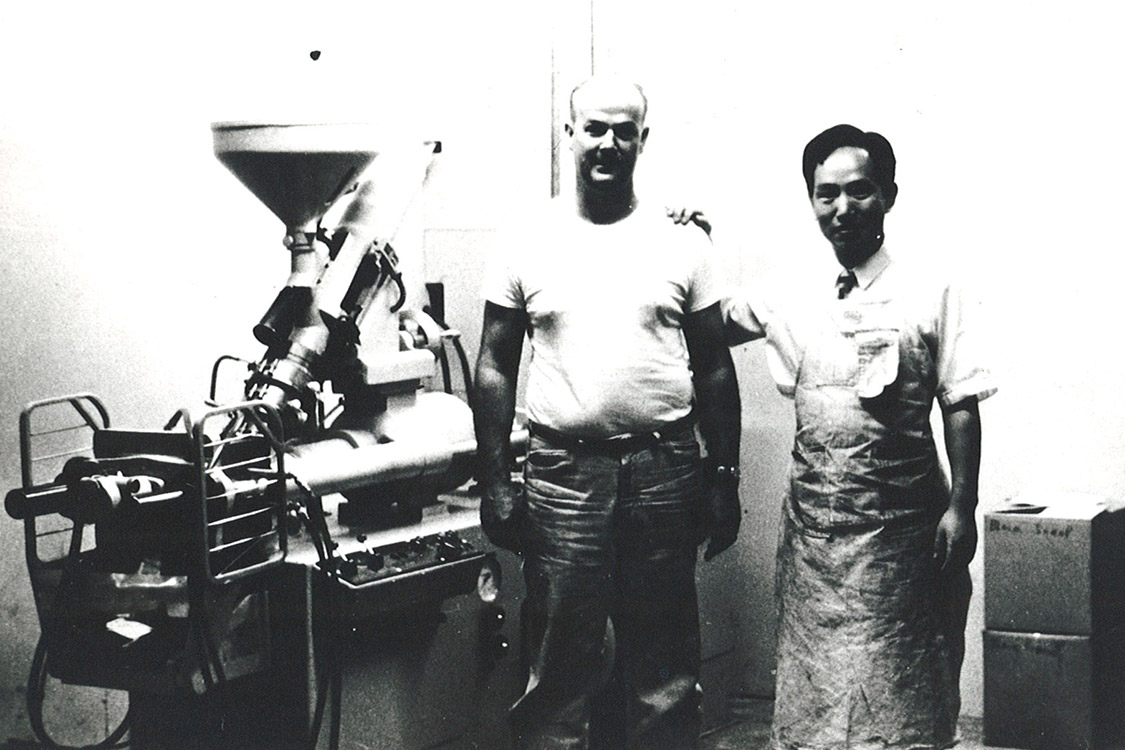

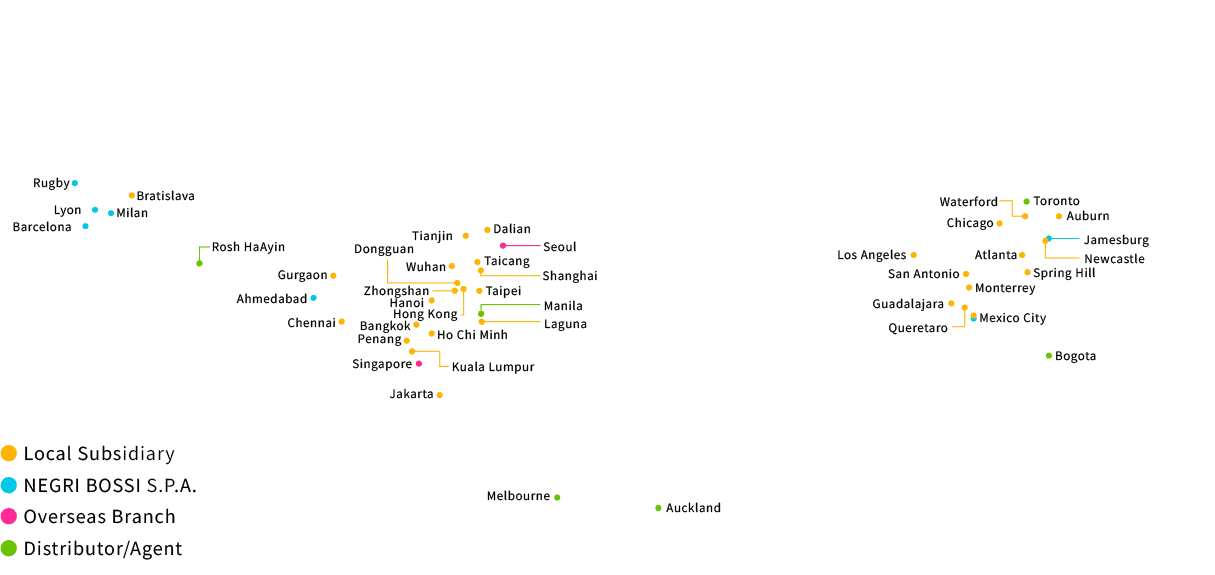

Network and Sales Over 80 Countries

NISSEI has delivered their injection molding machines to over 80 countries. By precisely meeting the market needs in each country, region, and industry, NISSEI established its reputation as a trustworthy brand. Centered around their 14 overseas subsidiaries and branches, NISSEI’s elaborate network of sales and service bases spread over 47 locations in 23 countries.

NISSEI’s Sustainability Efforts

Establishing a Sustainable Society

“As a global company, NISSEI will enrich communities through plastics” is NISSEI’s corporate philosophy. To achieve this, NISSEI believes it is necessary to provide solutions to various social issues by leading and uniting the plastic industry to protect the global environment together.

Inclusive Growth

To Achieve a Truly Affluent Society