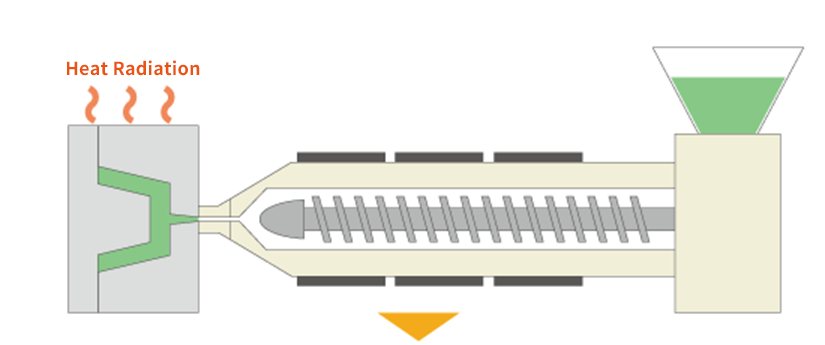

How are plastic products made? In the injection molding process, plastic products are molded through the following steps. Below shows how the injection molding machine works, and how plastics products are made.

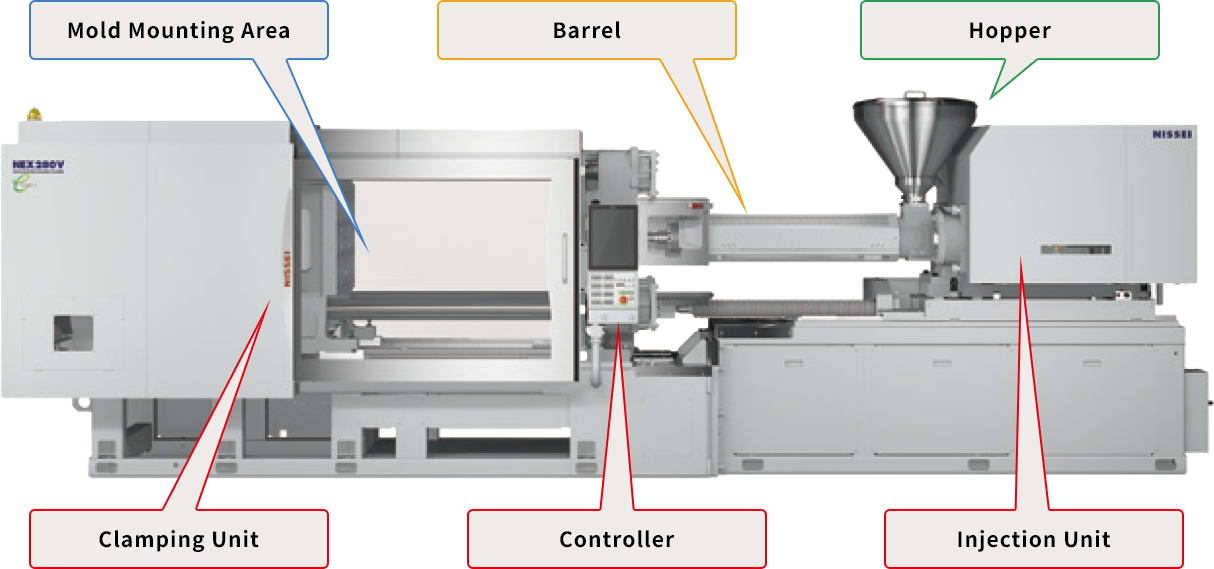

Mechanisms of the Injection Molding Machine

-

- Mold

- A set of steel blocks with a cavity where molten resin is injected to form molded products.

-

- Barrel

- An apparatus that heats and melts plastic materials (pellets) and applies pressure to fill molten resin into a mold.

-

- Hopper

- A tank that holds rice grain-shaped plastic material known as pellets.

Process

-

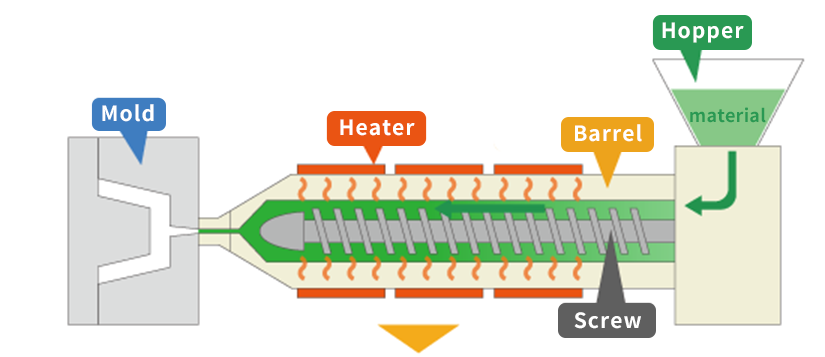

Melt

Rice grain-shaped plastic materials are heated (200-300°C) in the barrel to be melted into a syrup-like substance.

-

Inject

The melted material is injected into the mold under pressure just like a syringe.

-

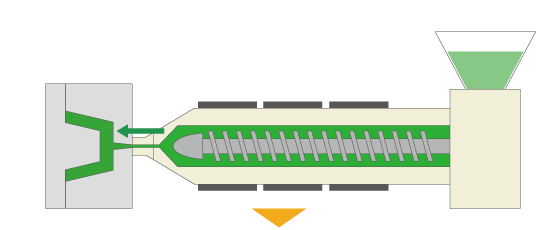

Solidify (Pressure Holding and Cooling)

The molten plastic injected into the mold is cooled under pressure for a few seconds to a few minutes until it hardens.

-

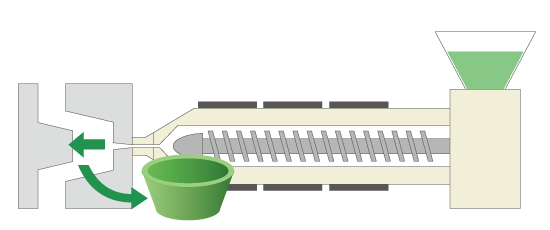

Take Out (Mold Open and Product Take Out)

After the product has solidified, the mold is opened to take out the finished product.