-

YA-1

YA-1 type was developed in August 1955. This model was equipped with technologies that were based on NISSEI’s founder Katashi Aoki’s ideas attained through operating mold processing business, such as its valves actuated by cams. It was the cornerstone of NISSEI’s transformation into an injection molding machine manufacturer.

-

YD-2

YD-2 type was manufactured in October 1957. This model was equipped with a revolutionary hydraulic drive system and was highly reputed as a fast injection molding machine.

-

TS-100

TS-100 type was a masterpiece that NISSEI developed in March, 1963. It combined the rotary ram type in-line screw injection mechanism, which possessed the highest plasticizing capacity, with unique direct pressure/mechanical clamping unit. This machine was the first-born of the TS Series.

-

FS-75

High-speed injection molding machine 250-FS type was developed in December 1970 to be exported to the US market. FS-55 type was released in February 1971, and it became a series. The series brought significant upgrades to highly-reputed TS Series. FS-75 was developed in 1972 as a “silent injection molding machine” and had attracted a wide attention in the industry. These machines are still widely used in the industry today.

-

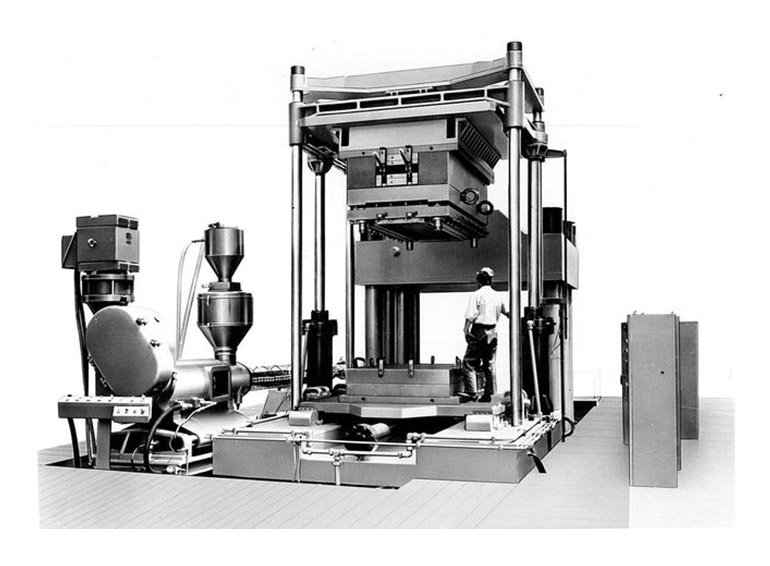

ULV-1

Ultra-large injection molding machine ULV-1 type was developed in April 1971. It offered 4,500-ton clamping force, vertical slide type mold change capability, high pressure clamping performance, and 3-stage product ejection mechanism.

-

MM-5

NISSEI revealed the world’s first electric servomotor driven (precision control) super-stable micro precision injection molding machine MM-5 in June 1983. The introduction of electric servomotor drive in injection molding machine allowed high-mix low-volume production of micro precision parts possible.

-

UH1000

UH1000 type was developed as an ultra high-speed filling injection molding machine in February 1992. Thanks to the closed-loop system by its unique mechanism and digital servo control, the machine could reach 10 to 20 times faster injection speeds than conventional injection molding machines of the time with excellent repeatability.

-

PNX40

The PNX Series was developed in 2005. The series machines offered excellent all-round performance and were equipped with a revolutionary hybrid pump system that combined the benefits of hydraulic presses (durability of direct pressure clamp, low maintainability, longevity, and low cost) and all-electric presses (energy efficiency, high repeatability, and high response).

Corporate Information